Optimizing Heat Exchanger Maintenance with the FI80E Back Facing Kit

Heat exchangers are a vital component in the chemical industry, responsible for efficient thermal energy transfer between fluids. However, after years of service, heat exchangers face significant challenges with sealing. In high-temperature and humid environments, corrosion can lead to leaks in the sealing surface, compromising the system's efficiency and safety. The unique structure of heat exchangers presents additional complications when performing repairs on sealing faces, as traditional internal mounted flange facing machines cannot effectively service these critical parts. This challenge has long plagued onsite machining teams, requiring a robust and versatile solution.

At MT Portable Machine, we have always been committed to providing innovative solutions for our customers' most demanding tasks. In response to the specific challenges of servicing heat exchanger flanges, we designed and developed a comprehensive set of repair kits specifically tailored to meet these needs. These kits are fully compatible with our standard FI80E Flange Facing Machine, offering unmatched flexibility and performance for heat exchanger maintenance. The kits include:

1. Heat Exchange Mounting Kit / FI80-08-01A

The Heat Exchange Mounting Kit is designed to securely attach the machine to the heat exchanger tube sheet. We engineered a unique spring collect that allows screws to be fixed inside the heat exchanger tubes, ensuring a stable connection. The heat exchanger mounting plate is then securely fastened to the tube sheet, and the main body of the machine is installed. This custom design ensures that the FI80E Flange Facing Machine can be used effectively for heat exchanger repairs.

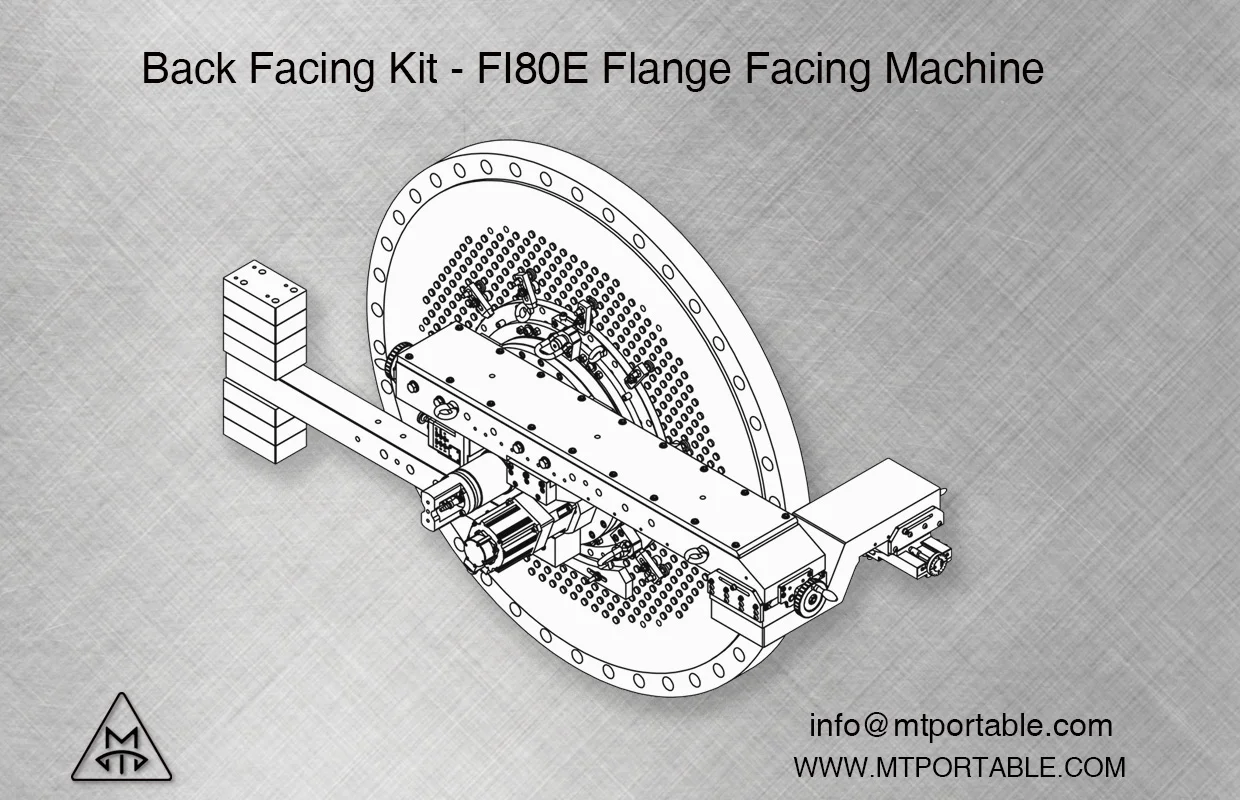

2. Back Facing Kit / FI80-09-01A

The Back Facing Kit is specifically designed for machining the backside of heat exchangers. It can be easily mounted on the existing tool post slide of the FI80E, utilizing the same tool holder already available with the machine. This cost-effective solution allows operators to machine the external cylindrical surface as well as the flange sealing surface on the back of the heat exchanger, ensuring precise and efficient repairs.

3. Base Centraliser Kit / FI80-10-01A

The Base Centraliser Kit is designed to help operators quickly and accurately align the heat exchanger mounting kit, minimizing installation risks. This kit helps to maintain proper positioning during the repair process, ensuring the machine is centered and stable throughout the operation. It significantly enhances the ease of use and safety of the equipment.

In addition to these core kits, we also developed a special mounting kit for heat exchanger head sealing faces, featuring partition plates. This design allows the technician to bypass partition plates during repairs, utilizing existing support legs for internal clamp-type installations. This innovative solution reduces costs while maintaining the machine’s performance and flexibility.

At MT Portable Machine, our focus remains on providing reliable, high-quality onsite machining solutions to meet the ever-evolving needs of industries worldwide. We continue to innovate, ensuring that our equipment not only meets the highest standards of performance but also offers cost-effective solutions for our customers. If you are facing challenges with heat exchanger maintenance, our expert team is ready to assist. Please contact us at info@mtportable.com for more information on how our FI80E Back Facing Kit and other onsite machining solutions can optimize your operations.