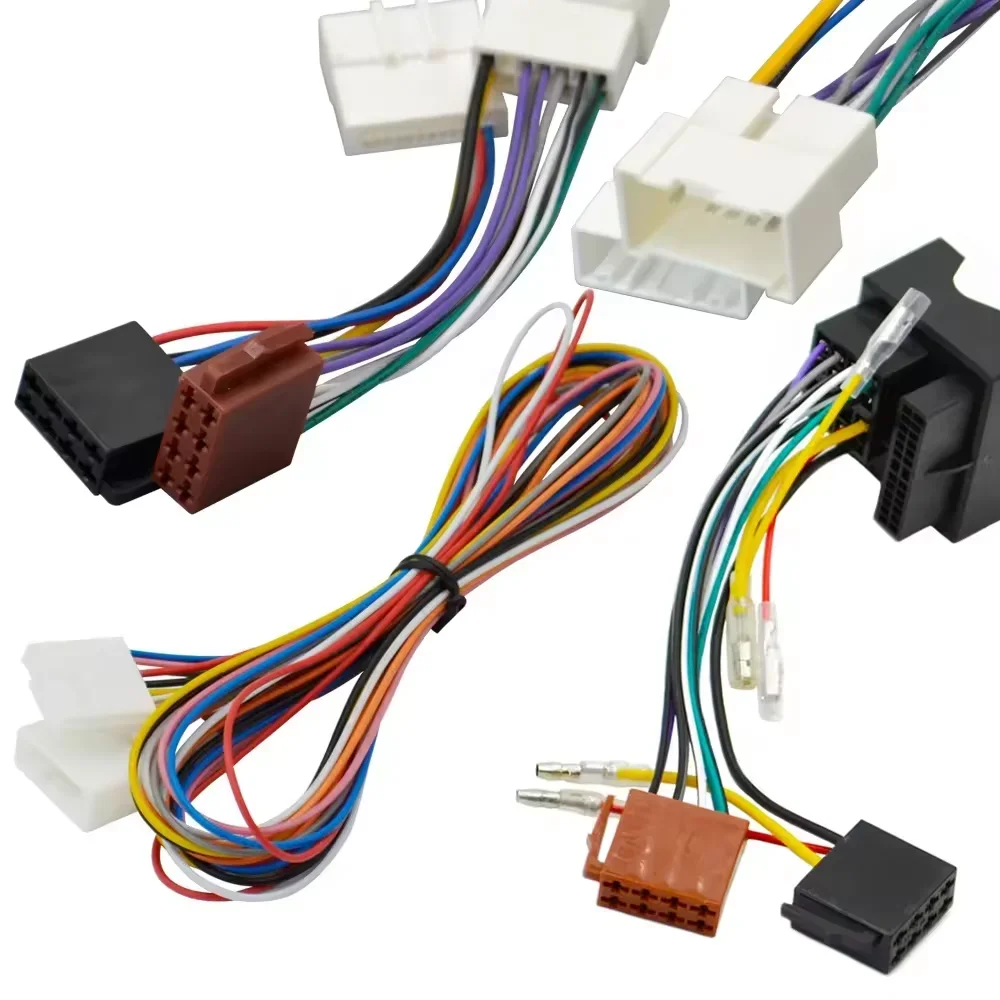

Automotive wiring harness systems are the backbone of any vehicle's electrical system, providing the critical connections between the vehicle's electrical components. These systems ensure that everything from the engine control module (ECM) to the headlights functions smoothly. However, wiring harness systems can sometimes face issues that affect vehicle performance. When problems arise, troubleshooting the wiring harness quickly and effectively is essential to avoid costly repairs and ensure vehicle safety.

In this article, we will explore common issues encountered in automotive wiring harness systems and how companies like Xinying, a leader in the production of electronic wires, terminal harnesses, connector harnesses, and high-temperature wire harnesses, offer solutions to these problems.

Common Problems in Automotive Wiring Harness Systems

Before diving into troubleshooting, it’s essential to understand the typical problems that can occur in automotive wiring harness systems. Some common issues include:

Broken or Frayed Wires

Loose or Corroded Connectors

Damaged Insulation

Short Circuits

Poor Connections

Heat Damage

Each of these issues can cause a variety of electrical failures in a vehicle, ranging from non-functioning lights to complete engine failure. Let’s now take a look at how to identify and solve these problems.

Broken or Frayed Wires

Broken or frayed wires are a frequent issue, especially in older vehicles or those that have been subjected to harsh conditions like high heat or humidity. Over time, the protective insulation may wear away, exposing the wire to potential damage or corrosion.

Troubleshooting Steps:

Inspection: Conduct a visual inspection of the wiring harness to check for any visible signs of wear, such as fraying, cracking, or exposed wires.

Continuity Testing: Use a multimeter to test the continuity of the wire. If there is no continuity, the wire is likely broken or damaged and needs replacing.

Replace Damaged Wires: If a wire is broken or severely damaged, it is crucial to replace it. Ensure that you are using high-quality, durable wire, such as Xinying's electronic wires, to prevent future issues.

Loose or Corroded Connectors

Connectors are a common point of failure in wiring harnesses. Over time, connectors can become loose or corroded, especially in areas where moisture or dirt may have accumulated. Corrosion can increase electrical resistance, leading to poor performance or even system failures.

Troubleshooting Steps:

Visual Inspection: Check for visible corrosion on the connectors. Look for greenish or whitish discoloration, which is a sign of corrosion.

Tighten Connectors: If a connector is loose, gently tighten it or replace any faulty locking mechanisms to ensure a secure connection.

Clean Corroded Connectors: For corroded connectors, use a specialized electrical contact cleaner to remove corrosion. For severe cases, replace the connectors entirely with high-quality connector harnesses from trusted suppliers like Xinying.

Apply Dielectric Grease: After cleaning or replacing connectors, apply dielectric grease to help prevent further corrosion and improve the longevity of the connection.

Damaged Insulation

The insulation surrounding the wires in a wiring harness helps protect the wires from external damage and prevents short circuits. If the insulation is damaged or worn, it could expose the wires to abrasion, moisture, or heat, which can lead to system malfunctions.

Troubleshooting Steps:

Inspect for Visible Damage: Look for areas where the insulation is cracked, cut, or missing.

Wrap Damaged Sections: If the damage is minimal, you can repair the insulation with electrical tape or heat shrink tubing. However, this is only a temporary solution.

Replace Damaged Wires: For more severe damage, replace the affected wire or harness. Use high-quality high-temperature wire harnesses from suppliers like Xinying, which offer superior insulation and protection against harsh conditions.

Short Circuits

A short circuit occurs when two wires that should remain separate come into contact, allowing electricity to flow where it shouldn’t. This can cause fuses to blow, damage electrical components, or even create fire hazards.

Troubleshooting Steps:

Check for Short Circuit Signs: A blown fuse, smoke, or sparking near the harness can be indicators of a short circuit.

Test Continuity: Use a multimeter to test for continuity between wires that should not be connected. If there’s continuity, a short circuit is likely present.

Inspect Wiring Layout: Examine the wiring layout for any exposed wires or areas where the wires may be touching metal surfaces or other conductors. Ensure that all wires are properly routed and insulated.

Replace Affected Wiring: If a short is detected, replace the damaged wiring and ensure that the new wire is properly insulated and routed to prevent future shorts.

Poor Connections

Poor connections, such as loose terminals or mismatched connectors, can cause intermittent electrical problems. This can result in inconsistent performance of components like lights, sensors, or motors.

Troubleshooting Steps:

Check Connector Pins: Inspect the pins and terminals inside the connectors for signs of wear, corrosion, or bending.

Ensure Secure Connections: Disconnect and reconnect each terminal to ensure a proper fit. If a terminal is loose or damaged, replace it with a new one.

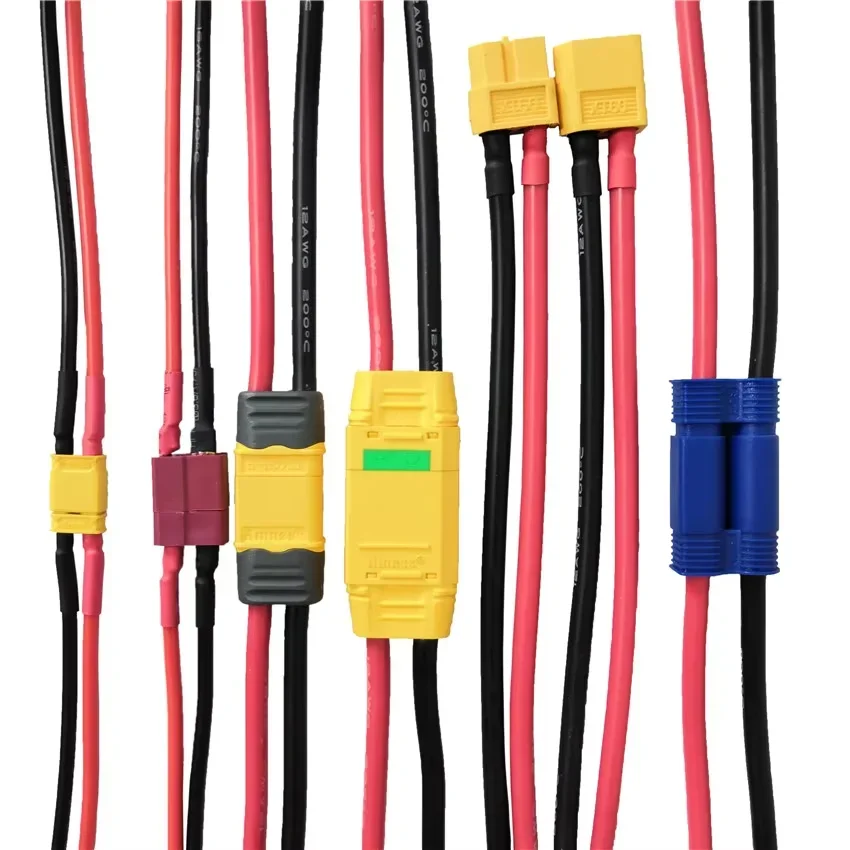

Use Quality Terminals: Use high-quality terminal harnesses from reliable suppliers like Xinying to ensure that connectors are secure and reliable.

Heat Damage

Automotive wiring harnesses are exposed to high temperatures, particularly in the engine bay. Over time, excessive heat can damage the insulation, melt wires, or degrade the integrity of the harness.

Troubleshooting Steps:

Inspect Areas of High Heat Exposure: Pay particular attention to wiring near the engine, exhaust components, and other heat-generating parts of the vehicle.

Replace Damaged Wires: If heat damage is visible, replace the affected wires or harnesses. Xinying's high-temperature wire harnesses are an excellent choice for areas that experience extreme heat.

Insulate or Reroute Wires: In some cases, rerouting the wires away from heat sources or adding additional heat shielding can help prevent further damage.

Why Choose Xinying for Your Wiring Harness Needs?

As a professional manufacturer of various types of electronic wires, terminal harnesses, connector harnesses, and high-temperature wire harnesses, Xinying offers reliable, high-quality solutions to automotive wiring issues. With a focus on durability, precision, and performance, Xinying’s products are designed to withstand the demands of the automotive industry.

High-Quality Materials: Xinying uses only premium materials that meet international standards, ensuring that the wiring harnesses they produce are long-lasting and reliable.

Custom Solutions: Xinying offers tailored solutions for unique wiring needs, ensuring that each harness is designed to fit the specific requirements of the vehicle.

Advanced Manufacturing: With state-of-the-art manufacturing facilities and strict quality control, Xinying produces products that meet the highest standards of performance and safety.

Conclusion

Troubleshooting problems in automotive wiring harness systems can be challenging, but with the right tools and knowledge, you can identify and resolve issues quickly. From broken wires to short circuits and heat damage, understanding common wiring problems and knowing how to fix them can save time and money. Working with trusted suppliers Xinying, who specialize in high-quality wiring harnesses, ensures that your automotive electrical systems remain in top condition and perform reliably.

Exploring the Uses of Auto Wiring Harnesses in Automotive Engineering