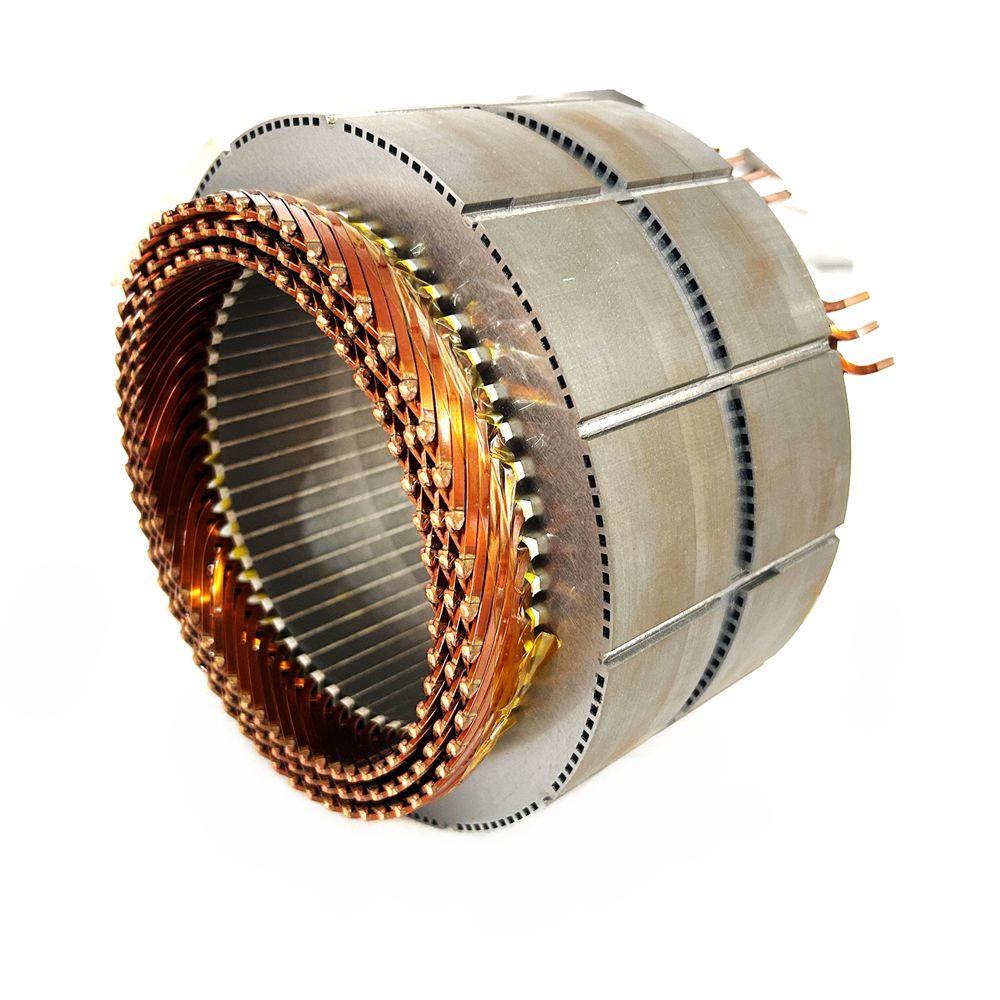

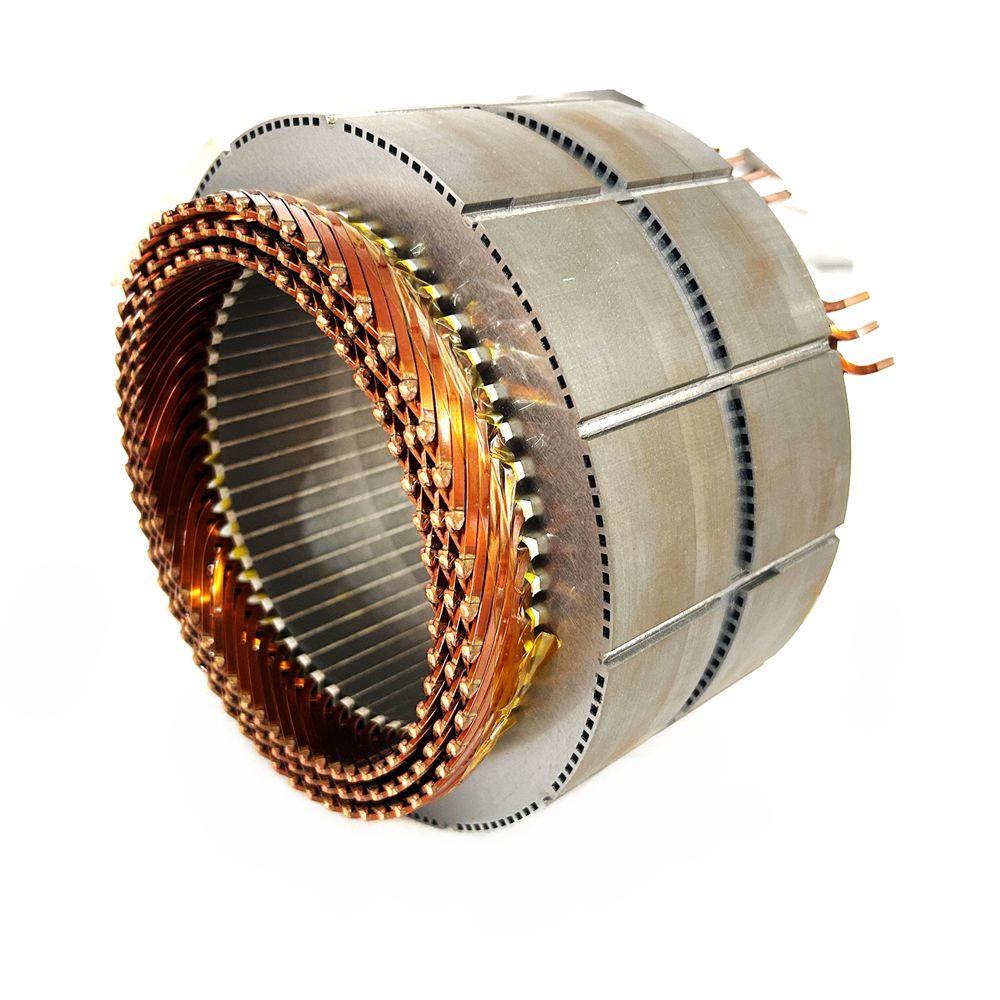

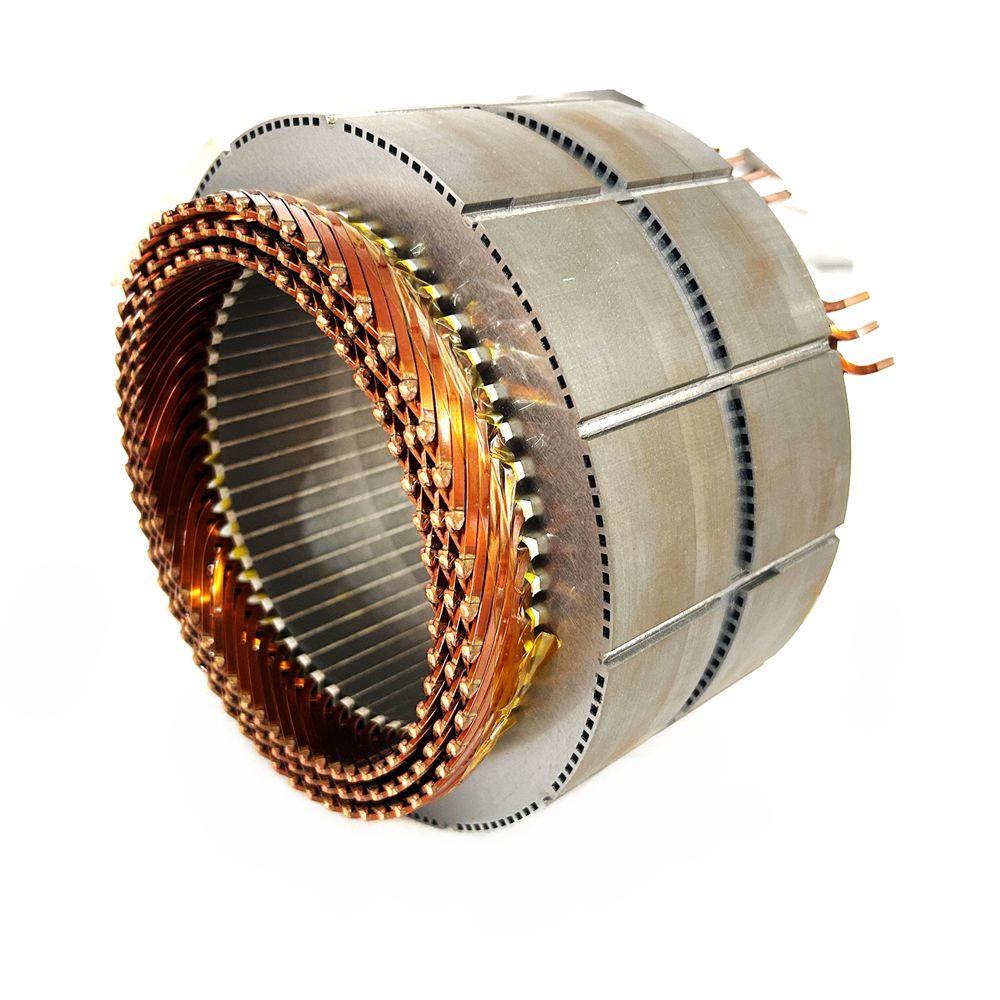

In today’s rapidly evolving world of new energy solutions, one of the critical components driving efficiency and innovation is the motor stator assembly. Whether it’s for electric vehicles, renewable energy systems, or industrial applications, optimizing stator designs can significantly enhance performance, reduce energy consumption, and improve reliability. For companies like Longnai, a leader in the development and manufacturing of motor prototypes, the ability to customize stator assemblies plays a crucial role in meeting the diverse needs of modern energy systems.

The Role of Motor Stators in New Energy Systems

A motor stator is a key component in an electric motor, serving as the stationary part that generates the magnetic field necessary for the motor’s operation. It works in tandem with the rotor, which rotates to produce mechanical power. In the context of new energy solutions, the stator's design can impact various performance factors such as energy efficiency, heat dissipation, and overall durability.

As industries move toward electric-powered solutions, the demand for high-performance, customized motor stators grows. Tailoring these assemblies allows engineers to optimize motor performance for specific energy systems, such as electric vehicles (EVs), wind turbines, or solar-powered appliances.

Why Customization Matters

No two applications are the same. Different industries and technologies require unique specifications when it comes to motor stator assemblies. Customization offers a range of advantages, including:

Improved Efficiency: By fine-tuning the stator’s design, energy loss can be minimized, leading to higher overall efficiency for motors used in energy systems.

Cost-Effectiveness: Tailored solutions can help companies avoid over-engineering, ensuring that they are using just the right components for the job without wasting resources.

Enhanced Performance: Motors in specialized applications like EVs or industrial machinery may need specific design considerations, such as increased torque output or better thermal management. Customization ensures these needs are met.

Extended Durability: A well-designed stator assembly can improve the longevity of the motor, which is essential for applications where high operational reliability is paramount.

Longnai’s Approach to Stator Assembly Customization

Longnai, a prominent company specializing in the research and manufacturing of motor samples, has a wealth of experience in customizing motor stator assemblies for diverse applications. Their team works closely with clients to develop solutions that meet both performance and cost requirements. Here's how Longnai ensures a high level of customization:

1. Design Flexibility

Longnai offers full design flexibility, allowing clients to request specific dimensions, materials, and winding configurations that suit the particular needs of their application. Whether it’s increasing the power density for a compact electric vehicle motor or designing a stator that performs optimally in extreme temperatures, Longnai’s design team can tailor solutions to suit.

2. Advanced Simulation and Prototyping

Before mass production, Longnai employs advanced simulation tools to model the motor’s behavior under various operating conditions. This ensures that the customized stator will perform as expected in real-world applications. Additionally, the company provides rapid prototyping services, enabling clients to test and refine designs quickly.

3. Material Selection

The choice of materials is critical when designing a stator assembly. Longnai works with a wide variety of materials, including high-grade steel, copper, and advanced composites, to meet the specific requirements of energy efficiency, heat resistance, and magnetic properties. With their expertise, Longnai helps clients select the best material for their application.

4. Quality Control and Reliability Testing

Longnai’s commitment to quality ensures that every customized stator assembly undergoes rigorous testing to meet industry standards. Whether it’s vibration testing, thermal testing, or electromagnetic compatibility (EMC) testing, Longnai guarantees the durability and reliability of its motor stator assemblies under demanding conditions.

Applications of Customized Stator Assemblies

Customized stator assemblies are used in a variety of industries, and their applications are expanding as new technologies emerge. Some of the key sectors benefiting from Longnai’s tailored solutions include:

Electric Vehicles (EVs): With the rise of electric mobility, EV manufacturers require stator assemblies that maximize energy efficiency while minimizing weight and size. Longnai’s customization options allow for the development of stators that meet these requirements.

Renewable Energy: In wind and solar power systems, motors need to withstand extreme environmental conditions while offering optimal performance. Longnai’s stator assemblies are designed with durability in mind, ensuring reliability in harsh environments.

Industrial Machinery: Custom motor stators play a significant role in powering machinery used in manufacturing, automation, and robotics. Longnai’s high-performance designs enable precise control, longevity, and energy savings for industrial applications.

Home Appliances: For applications like electric fans, washing machines, and other household appliances, Longnai offers compact and energy-efficient motor stators that help optimize power consumption and performance.

The Future of Custom Motor Stators

As industries continue to demand higher performance, sustainability, and efficiency, the future of motor stator assemblies will be shaped by ongoing advancements in material science, manufacturing techniques, and motor control technologies. Companies like Longnai will continue to be at the forefront, driving innovation and providing tailored solutions for emerging energy applications.

Conclusion

The ability to customize new energy motor stator assemblies is crucial for optimizing performance and efficiency across diverse applications. By working with experienced manufacturers like Longnai, companies can develop motors that meet their exact specifications, improving both the functionality and sustainability of their energy systems. As the demand for cleaner, more efficient technologies grows, customized stator assemblies will play an essential role in shaping the future of energy.

High-Quality New Energy Motor Stators: Key Features and Benefits