Hydraulic motors are widely used in various industrial applications, including construction machinery, agricultural equipment, and manufacturing processes. These motors convert hydraulic energy into mechanical energy to produce rotational motion. Two of the most critical parameters that determine a hydraulic motor’s performance are torque and speed. Understanding how to calculate these values is essential for selecting the right hydraulic motor for your specific needs.

This article provides a comprehensive guide on how to calculate the torque and speed of a hydraulic motor, including the necessary formulas, factors affecting performance, and practical examples.

Understanding the Basics of Hydraulic Motors

Before diving into calculations, it is essential to understand the basic working principles of a hydraulic motor.

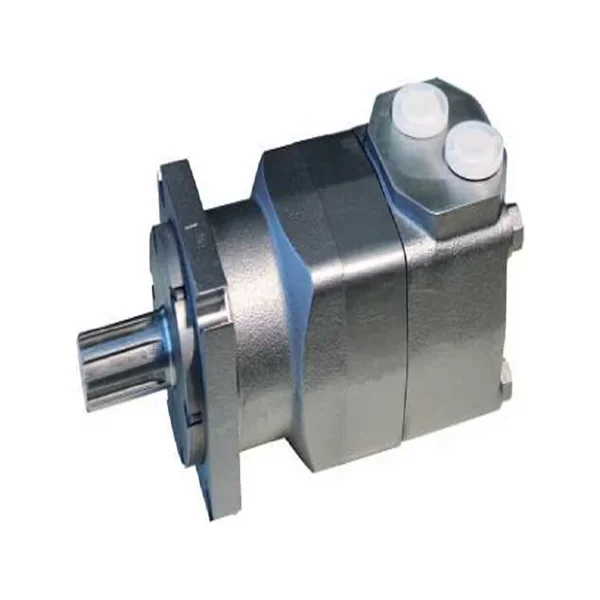

A hydraulic motor operates by using pressurized hydraulic fluid to generate rotational motion. It consists of components such as:

Drive shaft: Converts fluid power into mechanical power.

Rotary group: Includes gears, pistons, or vanes that enable rotation.

Hydraulic ports: Allow fluid flow into and out of the motor.

The performance of a hydraulic motor depends on parameters like pressure, displacement, and flow rate, which are crucial in torque and speed calculations.

How to Calculate Hydraulic Motor Torque

Torque is the rotational force that a hydraulic motor generates. It is calculated using the following formula:

Where:

T = Torque (Nm or lb-in)

P = Pressure drop across the motor (bar or psi)

D = Displacement of the motor (cc/rev or in³/rev)

π = 3.1416 (constant)

Example Calculation of Torque

Assume a hydraulic motor has:

A pressure drop of 150 bar (or 2175 psi) across the motor.

A displacement of 100 cc/rev (or 6.1 in³/rev).

Using the formula:

Thus, the motor will generate approximately 2387.3 Nm of torque.

How to Calculate Hydraulic Motor Speed

The speed of a hydraulic motor depends on the flow rate and displacement of the motor. The formula to calculate speed is:

Where:

N = Speed (rpm)

Q = Flow rate (L/min or GPM)

D = Displacement (cc/rev or in³/rev)

Example Calculation of Speed

Assume a hydraulic motor has:

A flow rate of 50 L/min (or 13.2 GPM).

A displacement of 100 cc/rev (or 6.1 in³/rev).

Using the formula:

Thus, the motor will operate at 500 rpm.

Factors Affecting Torque and Speed

Several factors influence the torque and speed of a hydraulic motor, including:

1. Hydraulic Pressure

Higher hydraulic pressure increases the torque output of the motor. However, excessive pressure can cause mechanical wear and system inefficiencies.

2. Flow Rate

A greater flow rate results in higher speed, assuming other factors remain constant. Controlling the flow rate helps regulate the motor’s operating speed.

3. Motor Efficiency

Hydraulic motors are not 100% efficient. Internal leakage and friction reduce the actual torque and speed output. Efficiency is typically between 85-95%.

4. Load Conditions

The amount of resistance or load applied to the motor affects both torque and speed. A higher load requires greater torque to maintain motion.

5. Temperature and Viscosity

Temperature changes affect the viscosity of the hydraulic fluid, impacting motor performance. Proper selection of hydraulic oil is essential for optimal operation.

Practical Applications of Torque and Speed Calculations

1. Industrial Automation

Engineers use torque and speed calculations to design hydraulic systems for conveyor belts, robotic arms, and material-handling equipment.

2. Agricultural Machinery

Hydraulic motors in tractors and harvesters require precise torque and speed settings to operate efficiently under varying loads.

3. Construction Equipment

Excavators and loaders use hydraulic motors for movement and lifting, requiring accurate calculations for performance optimization.

Conclusion

By mastering these calculations, industries can enhance productivity, reduce energy consumption, and extend the lifespan of hydraulic equipment. Whether in construction, agriculture, or industrial automation, accurate torque and speed calculations are essential for achieving optimal hydraulic motor performance.

Top 5 Applications of Hydraulic Motors in Industrial Machinery