High-Density Polyethylene (HDPE) sheets have gained immense popularity across a multitude of industries due to their durability, adaptability, and cost-effectiveness. As industries evolve and demand materials that can withstand harsh conditions while offering versatility, HDPE sheets have emerged as the material of choice. From construction to packaging, agriculture to automotive, HDPE sheets have established themselves as indispensable in modern manufacturing and production processes.

India, being one of the largest producers and exporters of HDPE sheets, plays a critical role in supplying high-quality products to the global market. With numerous HDPE plastic sheets exporters in Gujarat and Ahmedabad leading the way, India has cemented its position as a reliable supplier of this versatile material. In this article, we delve into the benefits of HDPE sheets and why they are so highly sought after by various industries worldwide.

What are HDPE Sheets?

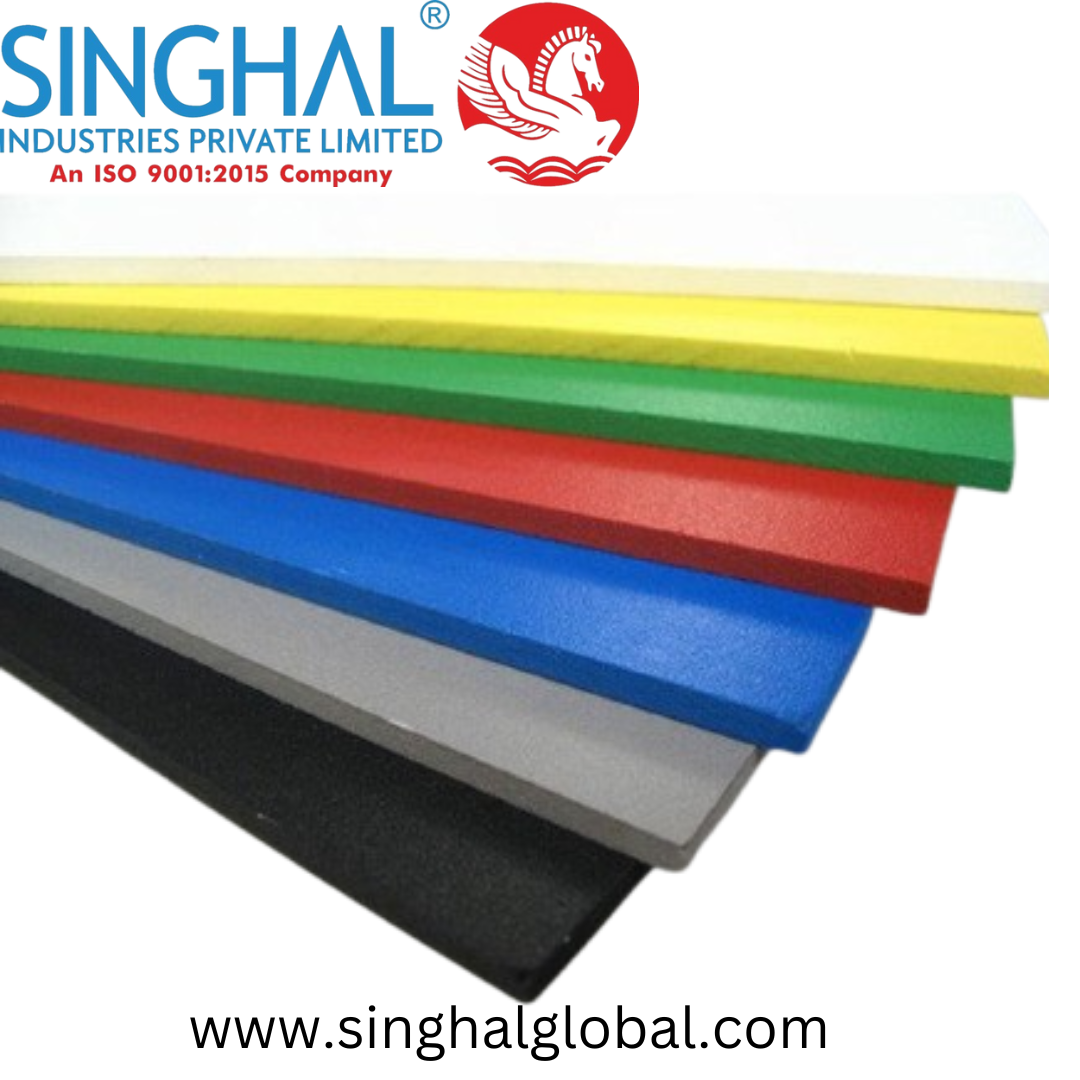

HDPE sheets are thermoplastic polymers made from petroleum. They are known for their exceptional strength-to-density ratio, chemical resistance, and lightweight properties. Due to these characteristics, HDPE sheets are utilized in diverse applications, such as the manufacturing of pipes, tanks, and packaging materials.

The adaptability of HDPE sheets makes them suitable for cutting-edge applications while still being affordable. HDPE sheets are widely available through HDPE polythene sheet suppliers in India, who cater to both domestic and international markets.

Benefits of HDPE Sheets

1. Durability and Strength

HDPE sheets are highly durable and possess excellent impact resistance. This makes them an ideal choice for applications where heavy-duty usage is required. Unlike other plastics, HDPE sheets do not crack or warp under pressure or extreme weather conditions. This quality has made HDPE products a favorite in the construction and automotive industries.

2. Versatility in Applications

One of the standout features of HDPE sheets is their versatility. They can be molded into various shapes, sizes, and thicknesses depending on the requirements of the industry. From packaging materials to chemical tanks and playground equipment, HDPE sheets are a perfect fit for countless applications.

3. Chemical Resistance

HDPE sheets are highly resistant to chemicals, including acids, alkalis, and organic solvents. This property makes them ideal for industrial applications where exposure to chemicals is inevitable, such as in chemical storage tanks and pipes.

4. Weather Resistance

Unlike many other materials, HDPE sheets can withstand extreme weather conditions without degrading. They do not absorb moisture and resist UV radiation, making them suitable for outdoor applications. This is particularly beneficial for industries such as agriculture and construction, where materials are often exposed to harsh environments.

5. Lightweight

Despite their durability, HDPE sheets are surprisingly lightweight. This makes them easy to transport and handle, reducing costs associated with logistics and installation.

6. Cost-Effective

HDPE sheets offer a cost-effective solution for industries looking for a durable and reliable material. They have a long lifespan and require minimal maintenance, ensuring that they remain a cost-efficient option over time.

7. Eco-Friendly

HDPE sheets are recyclable and considered an environmentally friendly material. They can be reprocessed into other plastic products, reducing waste and contributing to sustainability efforts globally.

Applications of HDPE Sheets

HDPE sheets are widely used across various industries due to their unique properties. Below are some of the key areas where HDPE sheets have made a significant impact:

1. Construction

In the construction industry, HDPE polythene sheet suppliers in India are used for making water tanks, sewage pipes, and barriers. Their ability to resist wear and tear, coupled with their lightweight nature, makes them a preferred choice for builders.

2. Packaging

HDPE sheets are extensively used in the packaging industry to produce containers, bottles, and caps. Their resistance to chemicals ensures that the packaged products remain safe and uncontaminated.

3. Automotive

In the automotive sector, HDPE sheets are used for manufacturing vehicle parts such as fuel tanks and interior panels. Their lightweight property helps in reducing the overall weight of the vehicle, improving fuel efficiency.

4. Agriculture

HDPE sheets are widely used in agriculture for applications such as greenhouse films, irrigation systems, and pond liners. Their ability to withstand harsh environmental conditions ensures long-lasting performance.

5. Marine Industry

HDPE sheets are also utilized in the marine industry for making dock fenders, boat linings, and buoyancy aids. Their water resistance and durability make them ideal for such applications.

The Role of India in HDPE Sheet Manufacturing and Export

India has emerged as a leading supplier of HDPE sheets globally, thanks to the robust network of manufacturers and exporters. Gujarat, in particular, has become a hub for HDPE plastic sheets exporters in Gujarat, supplying high-quality products to both domestic and international markets. The state boasts advanced manufacturing facilities and skilled labor, which enable it to produce HDPE sheets that meet global standards.

Similarly, Ahmedabad has established itself as a key player in the HDPE market, with HDPE products exporters in Ahmedabad offering a wide range of products. These exporters have earned a reputation for their reliability, timely delivery, and commitment to quality.

Choosing the Right Supplier

When sourcing HDPE sheets, it is crucial to choose the right supplier. Reliable HDPE polythene sheet suppliers in India offer products that adhere to strict quality standards, ensuring that they meet the requirements of various industries. Before finalizing a supplier, it is advisable to check their certifications, production capabilities, and customer reviews to ensure a smooth and satisfactory experience.

Conclusion

HDPE sheets have revolutionized the way industries approach material selection. Their durability, versatility, and cost-effectiveness make them an essential component in applications ranging from construction and packaging to agriculture and automotive. India, with its strong manufacturing base and skilled workforce, continues to be a leader in the global HDPE market. With a focus on quality and innovation, HDPE plastic sheets exporters in Gujarat and HDPE products exporters in Ahmedabad are driving the industry forward, ensuring that high-quality materials are available for diverse applications worldwide.

As industries continue to evolve and demand more from their materials, HDPE sheets are set to remain at the forefront, offering a reliable and eco-friendly solution for years to come.

Frequently Asked Questions (FAQs)

1. What makes HDPE sheets better than other types of plastic sheets?

HDPE sheets stand out due to their exceptional strength-to-density ratio, chemical resistance, and weather durability. They are lightweight, cost-effective, and recyclable, making them a preferred choice for a variety of applications across industries.

2. How do I select the right HDPE sheet supplier in India?

When choosing HDPE polythene sheet suppliers in India, ensure they have proper certifications, a reputation for delivering high-quality products, and the capability to meet your specific requirements. Checking reviews and past client feedback can also help in making an informed decision.

3. Are HDPE sheets eco-friendly?

Yes, HDPE sheets are eco-friendly. They are recyclable and can be reprocessed into new products, reducing plastic waste and contributing to sustainable practices in various industries.