Electroplating is a process used extensively across industries such as automotive, electronics and jewelry manufacturing. It involves depositing a layer of metal onto a substrate to enhance its appearance, protect it from corrosion or improve its conductivity. A key component in the electroplating process is the electrodeposited copper foil titanium anode plate. In this article, we will take a closer look at the role of this specialized anode plate.

What is Electrode-Posited Copper Foil Titanium Anode Plate?

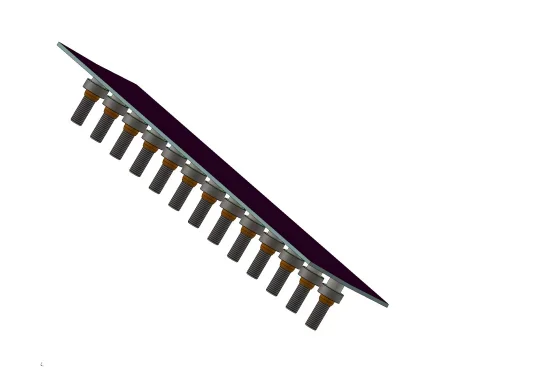

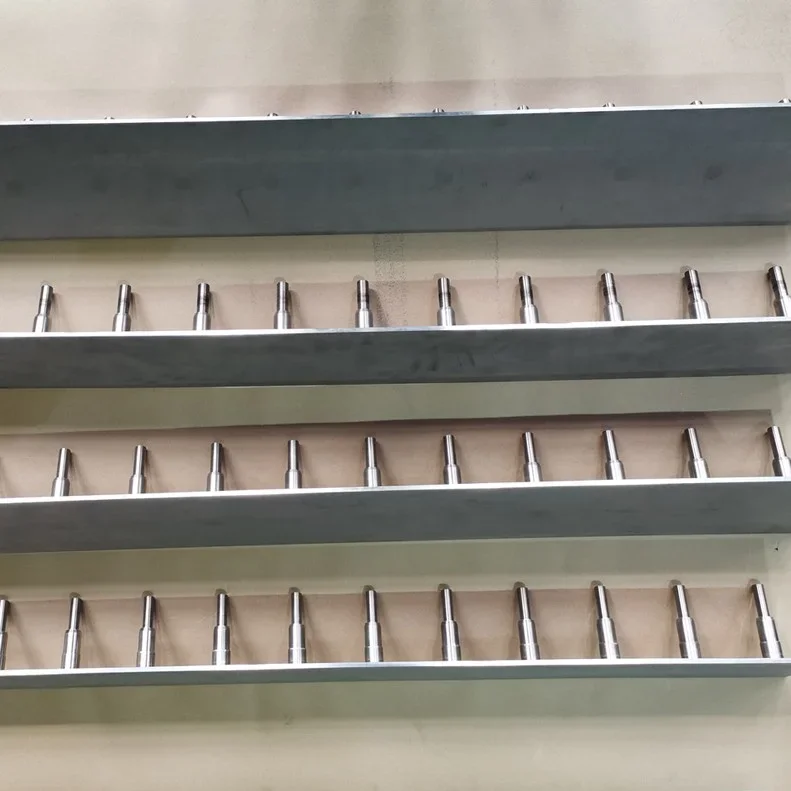

Electrode-posited copper foil titanium anode plate is a specialized component used in electroplating processes. It is composed of a thin layer of copper foil electrodeposited onto a titanium substrate. This combination of materials provides unique properties that make it ideal for electroplating applications.

The manufacturing process of electrode-posited copper foil titanium anode plate involves several steps. First, a titanium substrate is prepared by cleaning and polishing it to ensure a smooth surface. Next, a layer of copper foil is electrodeposited onto the titanium substrate using an electrochemical process. This results in a uniform and adherent copper layer on the titanium substrate, forming the electrode-posited copper foil titanium anode plate.

The Importance of Electrode-Posited Copper Foil Titanium Anode Plate in Electroplating

The electrode-posited copper foil titanium anode plate plays a crucial role in achieving high-quality electroplated finishes. Here are some key reasons why it is essential in electroplating processes:

Enhanced Durability and Longevity:

The combination of copper foil and titanium substrate provides excellent durability and longevity to the anode plate. Copper is known for its corrosion resistance, while titanium offers high strength and resistance to chemical attacks. This ensures that the anode plate can withstand the harsh electroplating environment and maintain its performance over time.

Improved Efficiency and Cost-effectiveness:

Electrode-posited copper foil titanium anode plate offers improved efficiency in electroplating processes. The copper layer on the anode plate has high electrical conductivity, allowing for efficient transfer of electrical current during the plating process. This results in faster plating times and increased productivity. Additionally, the use of titanium as the substrate reduces the overall weight of the anode plate, making it more cost-effective compared to solid copper anodes.

Consistent and Uniform Plating Results:

The electrode-posited copper foil titanium anode plate plays a crucial role in achieving consistent and uniform plating results. The copper layer on the anode plate releases copper ions into the electrolyte solution during the electroplating process. These copper ions migrate towards the substrate being plated, ensuring a uniform deposition of the metal layer. This helps to eliminate uneven plating, such as patchiness or thickness variations, resulting in high-quality finishes.

How Does Electrode-Posited Copper Foil Titanium Anode Plate Work?

To understand the role of electrode-posited copper foil titanium anode plate, it is essential to grasp the electrochemical reactions that occur during electroplating. Here is a simplified explanation of how it works:

Electroplating involves an electrolyte solution containing metal ions and an anode (positive electrode) and cathode (negative electrode). When an electric current is applied, the metal ions in the electrolyte are attracted to the cathode, where they gain electrons and deposit onto the substrate.

In the case of electrode-posited copper foil titanium anode plate, the copper layer on the anode plate releases copper ions (Cu2+) into the electrolyte solution. These copper ions migrate towards the cathode (substrate being plated) due to the electrical potential difference. At the cathode, the copper ions gain electrons and form a layer of copper metal on the substrate.

The electrode-posited copper foil titanium anode plate also plays a role in controlling the plating thickness. By adjusting the electrical current and the surface area of the anode plate, manufacturers can regulate the rate at which copper ions are released into the electrolyte, thereby controlling the thickness of the plated layer.

Advantages of Electrode-Posited Copper Foil Titanium Anode Plate

Electrode-posited copper foil titanium anode plate offers several advantages in electroplating processes. Some of the key advantages include:

Corrosion Resistance:

Copper is known for its excellent corrosion resistance, making electrode-posited copper foil titanium anode plate highly durable in the electroplating environment. It can withstand the corrosive effects of the electrolyte solution, ensuring long-term performance.

High Conductivity:

The copper layer on the anode plate provides high electrical conductivity, allowing for efficient transfer of electrical current during the electroplating process. This results in faster plating times and improved productivity.

Compatibility with Various Electrolytes:

Electrode-posited copper foil titanium anode plate is compatible with a wide range of electrolyte solutions used in different electroplating applications. This versatility makes it suitable for various industries and plating requirements.

Applications of Electrode-Posited Copper Foil Titanium Anode Plate

Electrode-posited copper foil titanium anode plate finds applications in various industries. Some of the common applications include:

Automotive Industry:

In the automotive industry, electrode-posited copper foil titanium anode plate is used for plating components such as bumpers, grills, and decorative trims. It enhances the appearance of these parts, provides corrosion resistance, and improves their durability.

Electronics Manufacturing:

Electronics manufacturers use electrode-posited copper foil titanium anode plate for plating printed circuit boards (PCBs) and electronic connectors. It helps to improve the conductivity of these components and protect them from corrosion.

Jewelry and Decorative Finishes:

In the jewelry industry, electrode-posited copper foil titanium anode plate is used for plating precious metals such as gold and silver onto jewelry pieces. It enhances the appearance of the jewelry, provides a protective layer, and improves its longevity.

Maintenance and Care for Electrode-Posited Copper Foil Titanium Anode Plate

To ensure optimal performance and longevity of electrode-posited copper foil titanium anode plate, proper maintenance and care are essential. Here are some maintenance tips:

Cleaning and Inspection:

Regularly clean the anode plate to remove any buildup of contaminants or deposits. Inspect the surface for any signs of damage or wear, such as scratches or pitting. Replace the anode plate if necessary.

Storage and Handling:

Store the anode plate in a clean and dry environment to prevent corrosion. Handle the anode plate with care to avoid any physical damage that may affect its performance.

Future Developments and Innovations in Electrode-Posited Copper Foil Titanium Anode Plate:

As technology continues to advance, we can expect further developments and innovations in electrode-posited copper foil titanium anode plate. Some potential areas of improvement include:

Advancements in Coating Technologies:

Researchers are exploring new coating technologies that can further enhance the durability and performance of electrode-posited copper foil titanium anode plate. These advancements may include the development of new surface treatments or protective coatings to improve corrosion resistance.

Integration of Smart Materials:

The integration of smart materials into electrode-posited copper foil titanium anode plate is another area of interest. Smart materials can provide real-time monitoring of the anode plate's performance, allowing for better control and optimization of electroplating processes.

Conclusion

The electrode-posited copper foil titanium anode plate plays a vital role in achieving high-quality electroplated finishes. Its durability, efficiency, and ability to produce consistent and uniform plating results make it an indispensable component in electroplating processes. With its corrosion resistance, high conductivity, and compatibility with various electrolytes, this specialized anode plate is widely used in industries such as automotive, electronics, and jewelry manufacturing. By understanding its role and proper maintenance, manufacturers can optimize their electroplating processes and achieve superior results. As technology continues to advance, we can expect further developments and innovations in electrode-posited copper foil titanium anode plate, leading to even more efficient and sustainable electroplating solutions.

the applications of electrode-posited copper foil titanium anode plate in water treatment