As the demand for renewable energy sources continues to rise, innovative technologies are becoming essential in enhancing efficiency and sustainability. One such advancement is the use of insulated copper bars, which play a crucial role in the electrical systems that support new energy applications. This article explores the benefits of insulation coating on copper bars, particularly in the context of the evolving energy landscape.

Understanding Copper Bars and Their Importance

Copper bars are widely recognized for their superior electrical conductivity and durability, making them an essential component in various electrical applications. They are commonly used in switchgear, transformers, and electrical distribution systems due to their ability to efficiently conduct electricity with minimal energy loss. However, as technology progresses, the integration of insulation coatings on these copper bars is proving to be a game-changer.

What is Insulation Coating?

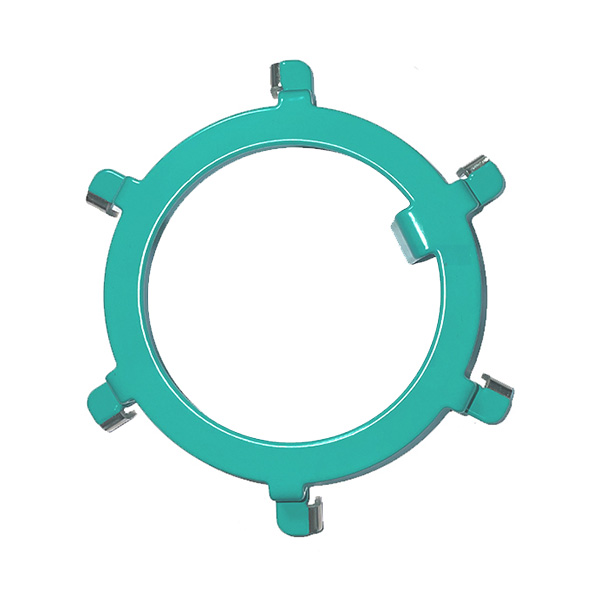

Insulation coating involves applying a protective layer to copper bars, enhancing their performance and longevity. This coating can be made from various materials, including epoxy powder or vinyl compounds, which provide excellent thermal and electrical insulation properties. The primary purpose of insulation is to prevent electrical leakage and protect against environmental factors that could lead to corrosion or degradation.

Benefits of Insulated Copper Bars

Enhanced Safety

One of the most significant advantages of using insulated copper bars is improved safety. The insulation layer reduces the risk of electrical shock and short circuits, protecting both personnel and equipment. By minimizing exposure to live conductors, insulated copper bars create a safer working environment in industrial settings.

Increased Reliability

Insulated copper bars contribute to greater reliability in electrical systems. The insulation helps prevent flashovers and short circuits caused by environmental factors such as moisture, dust, or chemical exposure. This reliability is particularly important in critical applications like renewable energy systems where downtime can result in significant financial losses.

Corrosion Resistance

Copper is susceptible to corrosion when exposed to harsh environments. Insulation coatings provide an additional barrier against moisture and contaminants, significantly extending the lifespan of copper bars. This resistance to corrosion not only enhances durability but also reduces maintenance costs over time.

Improved Thermal Management

The insulation coating on copper bars aids in thermal management by reducing heat generation during operation. This is particularly beneficial in high-performance electrical systems where excessive heat can lead to inefficiencies or damage components. By maintaining optimal operating temperatures, insulated copper bars enhance overall system performance.

Space Efficiency

Insulated copper bars can be designed to occupy less space while maintaining high conductivity levels. This compact design allows for more efficient use of space within electrical installations, which is especially valuable in densely packed environments like data centers or renewable energy facilities.

Versatility Across Applications

Insulated copper bars are versatile and can be utilized across various applications within the new energy landscape, including solar power systems, wind turbines, and electric vehicles. Their adaptability makes them suitable for both indoor and outdoor environments, ensuring reliable performance regardless of conditions.

Applications in the New Energy Landscape

The integration of insulated copper bars is particularly relevant in several key areas within the new energy landscape:

Renewable Energy Systems

In solar power installations, insulated copper bars are used for interconnections between solar panels and inverters. Their insulation helps protect against environmental factors while ensuring efficient energy transfer.

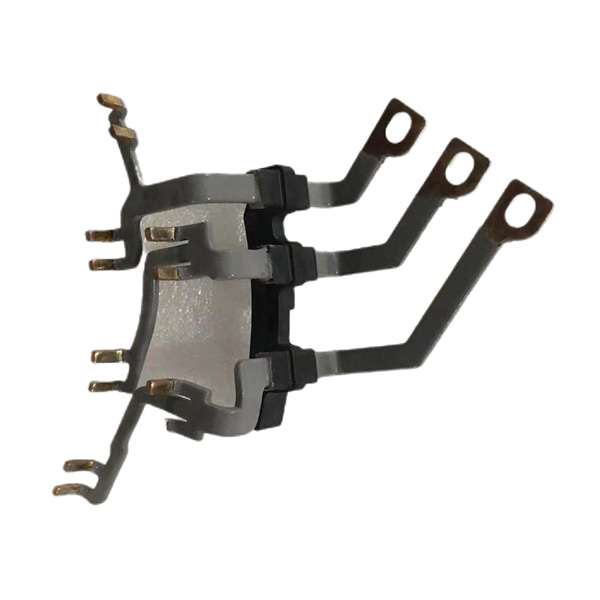

Electric Vehicles (EVs)

As electric vehicles become more prevalent, insulated copper bars play a critical role in battery management systems and power distribution networks within EVs. Their lightweight nature combined with excellent conductivity makes them ideal for these applications.

Smart Grids

Insulated copper bars are integral components of smart grid technology, facilitating efficient power distribution while minimizing losses due to resistance or environmental degradation.

Conclusion

As we navigate through the new energy landscape, the benefits of insulation coating on copper bars become increasingly apparent. From enhanced safety and reliability to improved thermal management and versatility across applications, insulated copper bars represent a significant advancement in electrical engineering.

Longnai Intelligent Co., Ltd., with its focus on innovative technology solutions, stands at the forefront of this transformation by providing high-quality insulated copper products tailored for modern energy needs. By leveraging these advancements, industries can achieve greater efficiency and sustainability as they transition towards a greener future. This exploration into insulated copper bars highlights their critical role in supporting new energy technologies while underscoring the importance of innovation in achieving sustainable solutions across various sectors.

Exploring the Role of Temperature Sensors in Charging Socket Safety